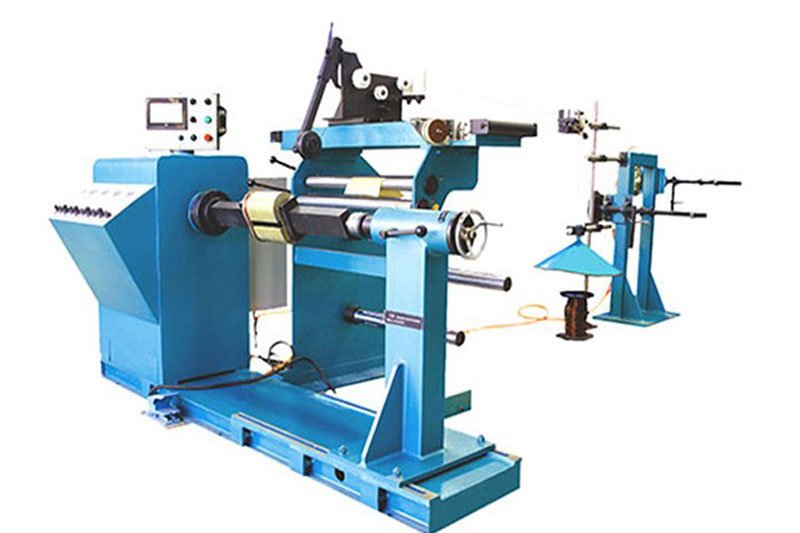

Power Transformer Winding Machine including a tubular steel frame.

there are four standard types of coil winders, you can find the right machine for almost all needs.

We also provide customized coil winders built to customer requirements.

it combines winding host, wire guider and wire decoiler,used in distribution transformers and Reactor.

suitable for round or rectangular wire winding to round, oval or rectangle coil.

Features for Power Transformer Winding Machine

1.with automatic wire guider makes sure that wire displacement synchronous with winding, guarantee minimum 0.01mm gap between each turn.

2.Max.speed can be 600rpm, speed improving 30%-200%

3.PLC control, just setting wire pitch and stopping at the desired turns.

Composition

winding host

automatic wire guider

insulation layer decoiler

round wire decoiler

Two axis flat wire decoiler with air brake

PLC control

Operation touch screen

Pneumatic system and foot pedal

SHUOHAO also offers foil winding machine,busbar machine,expandable mandrel and other transformer manufacturing equipment, any interested in,free contact with us.

| Model | GRX-600 |

| General | |

| Machine packed size | 2600×2200×1850mm |

| Machine whole Weight | 1000kg |

| Center height | 850mm |

| Distance between centers | 50-600mm |

| Power supply | 3 phase, 220V,50HZ or 380V,50HZ or 415V,60HZ or customer local voltage |

| Whole power | 4 KW |

| Coil | |

| Coil size | Diameter 60-500mm |

| Coil width (Max) | 500mm |

| Coil weight(Max) | 200kg |

| Coil cross section | Round,oval,rectangle |

| Conductors | |

| Round wire diameter | 0.3mm—Φ3mm |

| Winding shaft | |

| Speed adjustment method | Frequency stepless control |

| Rotation speed (Max) | 600rpm |

| Torque | 100Nm |

| Traverse type | AC Servo Motor driven with ball screw,gap between each turns 0.01mm |

| Wire traverse width | 500mm |

- $9000 – $13500 / Set FOB QINGDAO

- MOQ: 1 Set

- Shipping: Support Sea

- Delivery Time:30 DAYS

- After-sales Service Provided:

- Field maintenance and repair service, Field installation